- February 20, 2020

Home > News > Business development > Günsel introduces first TRNC domestic EV with Punch Powertrain electric drive

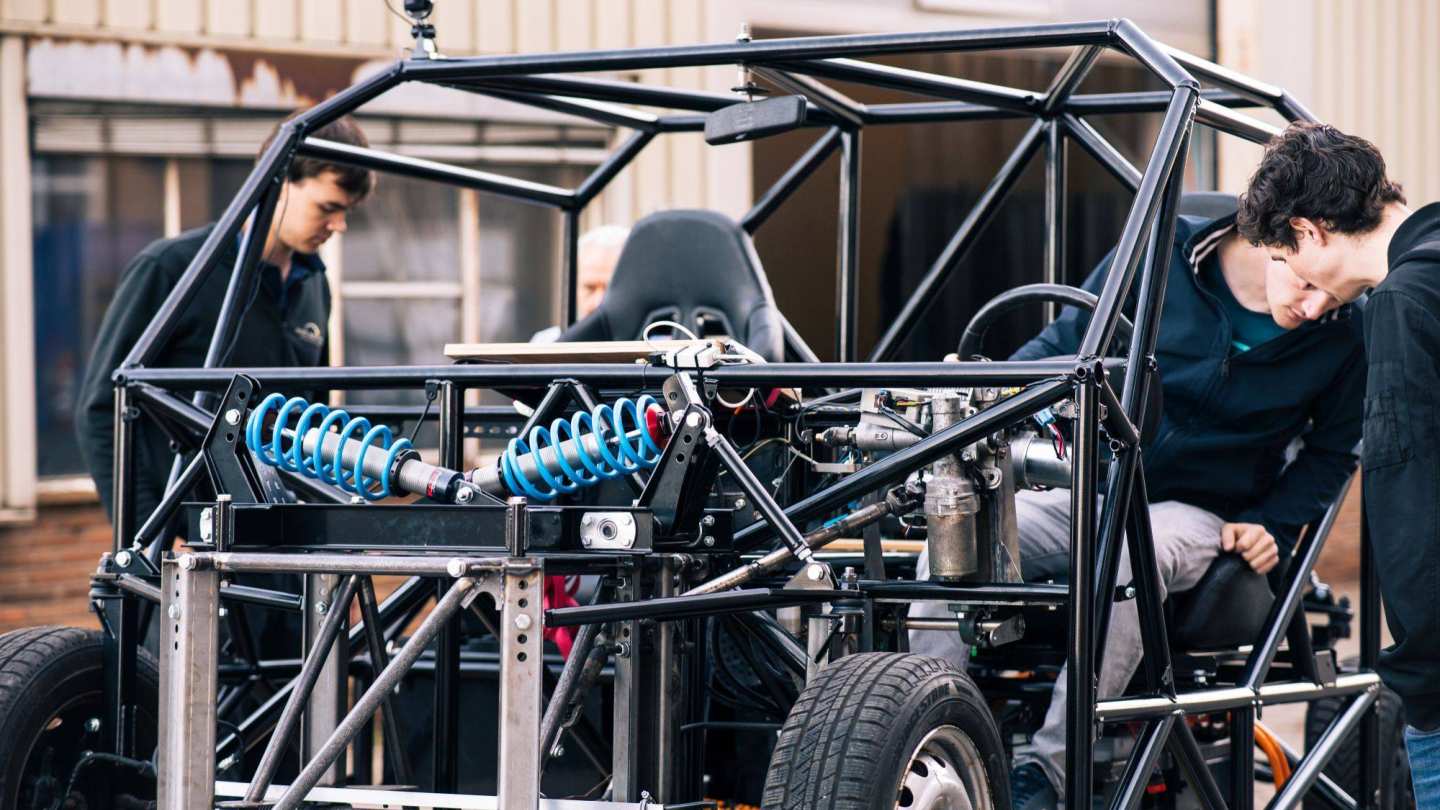

On the memorable date of 20-02-2020 Günsel introduced their first vehicle, Günsel B9, to the public. The vehicle represents a first TRNC native car brand, which aims at promoting electric driving and bringing sustainable growth to the region’s economy. As co-design partner, Punch Powertrain is contributing the electric drive unit: EP3.

First TRNC OEM

The Günsel car brand originated as Suat Günsel’s lifelong dream of producing an automobile, domestic to Turkish Republic of Northern Cyprus. In line with the vision that the future of automotive is electric, the B9 is created as an “Innovative, Efficient and Elegant” electric vehicle.

The development took place at Near East University, with over 1,2 million of work hours, spent over the course of past 10 years. Currently, over 100 engineers are working on the project. During 2021 the production of the first 2.000 units will start in a 20.000 m² Cyprus based facility, ramping up towards 20.000 vehicles per year by 2025.

Introducing full electric Günsel B9

Günsel B9 is designed to stand out, based on its performance and cost efficiency for the end user.

Among the measures to increase efficiency, is the use of composite and aluminum materials. Another measure is the regenerative braking system, which allows the recovery of heat energy, which is usually lost in conventional vehicles. This allows to bring down energy consumption, even under heavy traffic conditions.

Vehicle specifications:

- Power: 120kW (equivalent to 160 horsepower)

- 0 – 100km/h: 8s

- Range: 350km

- Preserves >90% battery capacity after 300.000 km

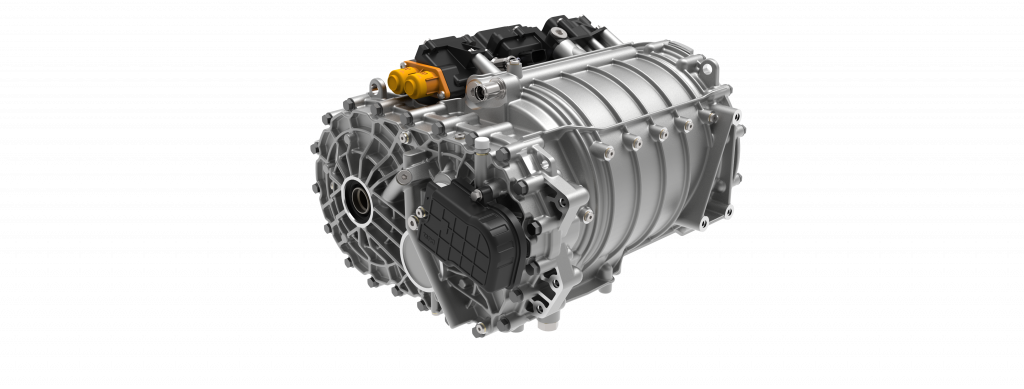

Electric drive (EP3) by Punch Powertrain

While an existing design would impose the changes to be incremental, this entirely new vehicle design allows the founders to incorporate the most novel technologies. The clean technologies, offered by Punch Powertrain, were a match to fulfil the high efficiency requirements.

EP3 is a next generation 3-in-1 electric drive, which tightly integrates an electric machine, a gearbox and an inverter into a single “drop-in” unit. The drive consists of latest cost optimal power components with reduced amount of rare earth materials, reduced weight and packaging. The EP3 contributes greatly to EV range maximization at an affordable price.