- December 8, 2021

Home > News > Development > Simulation Factory and Virtual Testing to halve development cycle time

The use of simulation in the product development and specifically in a virtual test environment is becoming increasingly important in the development of new products. Punch Powertrain applies a wide range of simulation tools and methods, that can support the engineers in the design phase and enable to validate the performance of their design, on different levels of complexity and integration, including at vehicle level. Hervé Bratec, Simulation Factory Leader at Punch Powertrain, explains.

Carrying out simulations and virtual tests on components and complete products enables Punch Powertrain to already verify the performance of its products without any physical production. For this, the company uses market leading commercial software, further complemented by self-developed tools, scripts and processes. These are used to modelize the complete transmission, all the mechanical and electronical parts, as well as the controls side as close to reality as possible. “The programs enable us to examine a wide range of highly detailed aspects of a product”, says Hervé. “Across all possible parameters: performance, driveability, durability, etc. We can predict the fuel consumption, acoustic performance, vibrations, the strength and wear, etc – on both component and transmission level. ”

Reducing time to market

Compared to physical testing the digital testing environment offers various advantages, Hervé explains. “Physical tests mostly provide either a fail or pass outcome. To understand why the fail or pass happened or how far a fail was from a pass, in-depth and time consuming analysis is required. With a virtual test, using simulations, that information is available much easier, based on the pre-defined level of accuracy.”

A second major advantage is the cost, as it eliminates the cost of physical preparations, as well as of production of physical parts and systems in house or by external parties. Therefore virtual simulations enable to reduce the cost of the test cycle with over 50%.

Furthermore, the expedited validation process further benefits our partners in the eco-system, such as component suppliers, enabling them to participate in the development process and to start their tooling build preparations at an earlier stage

All steps taken together, digital testing enables to shorten time to market and expedite product launches.”

Testing prior to engine availability

Also the benefits to the customer are clear: “We can already test the interaction between an engine and a gearbox, even though no physical engines and vehicles are available yet”, Hervé explains. “The complete engine block can be simulated using its main characteristic, given by the customer. The car itself is taken into the equation by entering its parameters, such as its weight and tire dimensions. This makes it possible to calculate, for instance, the transmission’s share in the fuel consumption. By changing the characteristics, we can check how our transmission is performing on different types of cars, such as an SUV, a sedan or a sports car.

As part of the transmission’s virtual assembly it can be pre-calibrated virtually: which entails fine tuning the control of the transmission for a specific vehicle. This will enable us to understand the transmission’s reaction with the same engine in different vehicles.”

AI to aid calibration

Going forward artificial intelligence will greatly support pre-calibration, says Hervé. “The AI can help by considering already known data and using it for new car models. A pre-calibration with AI could reduce the traditional calibration period of months to only a few weeks, fast tracking the whole process. ”

Physical and digital

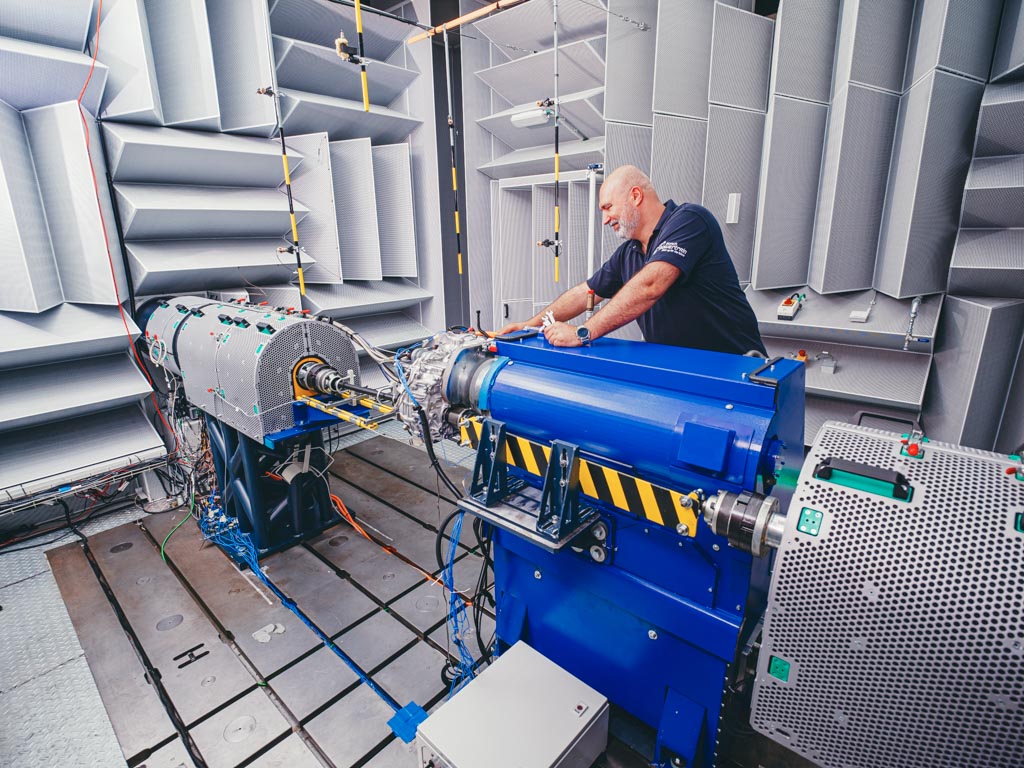

While offering many advantages, virtual testing is not there to fully replace physical test, Hervé points out. “Both are complementary. Virtual supports physical to select the most appropriate physical tests and it reduces unnecessary time and efforts spent. Physical supports virtual in making it more efficient and providing better results. Their combination offers us best of both worlds.”

Related news items