- July 15, 2024

In the fast-paced world of automotive power electronics, ensuring the reliability and performance of an EV inverter is one of the most crucial aspects of an electric vehicle (EV).

Electromagnetic Compatibility (EMC) testing plays a critical role in this process, ensuring that an inverter operates flawlessly without being affected by other electric vehicle systems in an increasingly connected and electrified automotive landscape. By focusing early on EMC design, simulation and testing, Punch Powertrain ensures that customer vehicles meet the required regulatory standards, deliver optimal performance, and maintain safety at an affordable cost.

What is EMC and why its testing for EV Inverters is so crucial?

Today’s electric vehicle (EV) systems rely on an increasing number of electronic components. Power converters benefit from new power components with higher switching frequency. Some vehicle architectures promote gathering more functionalities with same packaging. All this increases the risk of Electromagnetic Interference (EMI).

Electromagnetic Compatibility (EMC) refers to the capability of electronic devices and systems to operate without causing or experiencing issues in their electromagnetic environment. Testing EMC early in the inverter design process ensures that the inverter will not disturb the surrounding environment (such as other engine control units, radios, etc.) and that it will be immune to EMI generated by other electronics in the car or external sources.

Every electronic component in an electric vehicle (EV) generates two types of electromagnetic interference (EMI). The first type is radiated emissions, which are electromagnetic signals emitted through space. The second type is conducted emissions, which are signals transmitted through power and signal lines. Understanding the sources, characteristics, and propagation of these emissions is essential for designing effective EMC filters, intended to counter interference. By conducting thorough EMC testing early in the design of its EV inverter, Punch Powertrain ensures that it not only complies with global EMC standards but is also tuned and optimized to meet specific customer requirements.

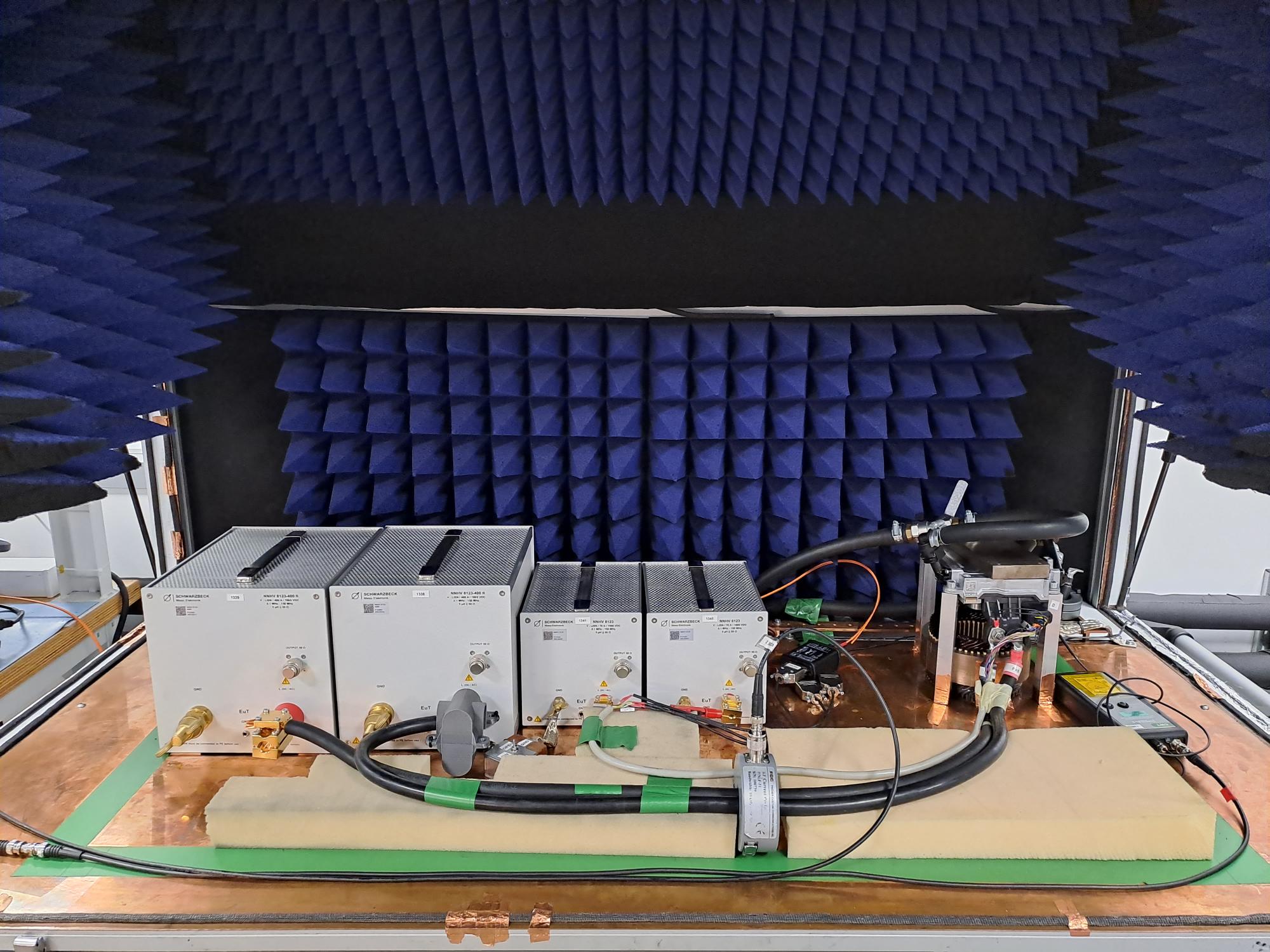

Saving time and cost through in-house testing

“The key to achieving minimum time and cost in developing a world-class EV inverter is an optimum design of the inverter, as well as early-stage EMC simulation and testing,” said Benoit Briane, Global Function Leader E-Drive. He further added, “We have strong expertise in designing EV inverters that generate minimal electromagnetic disturbance, and the opportunity to reach the optimal trade-off between EMC source reduction and filtering. With in-house capabilities for simulation and testing, we can validate our inverter and EMC filter designs at a very early stage of the project.”

In a typical scenario, more than one-third of the weight of an EV inverter is attributed to an EMC filter, depending on the emission level targeted by the customer. The cost, size, and weight of an EV inverter can be drastically reduced with an optimally tuned EMC filter. Our EV inverter design aims to reduce EMC emissions, thereby relieving a great part of the workload from the EMC filter. With advanced mechatronics integration, optimized EMC filter design and dedicated controls strategies, we have achieved one of the most advanced, compact, and high-performing 800V EV inverters.

Punch Powertrain has developed in-house capabilities for simulating the performance of EMC filters within the inverter environment. This allows pre-validation of the design on a virtual sample early in the project, reducing initial costs. This approach also offers greater robustness and shortens the validation time of physical samples. By avoiding major design changes at later stages of the development cycle, this approach prevents delays, reduces costs, and maintains customer confidence.

Results of the simulation and physical testing are correlated to further improve simulation performance and accuracy, levering experience for next projects. These entire process and mindset ensure that the final sample of the EV Inverter meets specific customer EMC demands as well as general EMC standard (CISPR25, …), and satisfies customer requirements on performance and quality within a tight project schedule.

Fast paced updates

When asked about the steps Punch Powertrain is taking to further enhance their EMC testing, Benoit Briane said, “As new electronic systems, features, and communication technologies are introduced in EVs, EMC standards and regulations are updated regularly to address the evolving challenges. Punch Powertrain is attentive to these developments, and we are continuously adding to and improving our EMC testing facilities and our methodologies to stay ahead of the curve.”