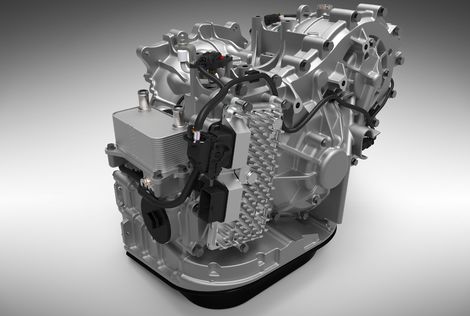

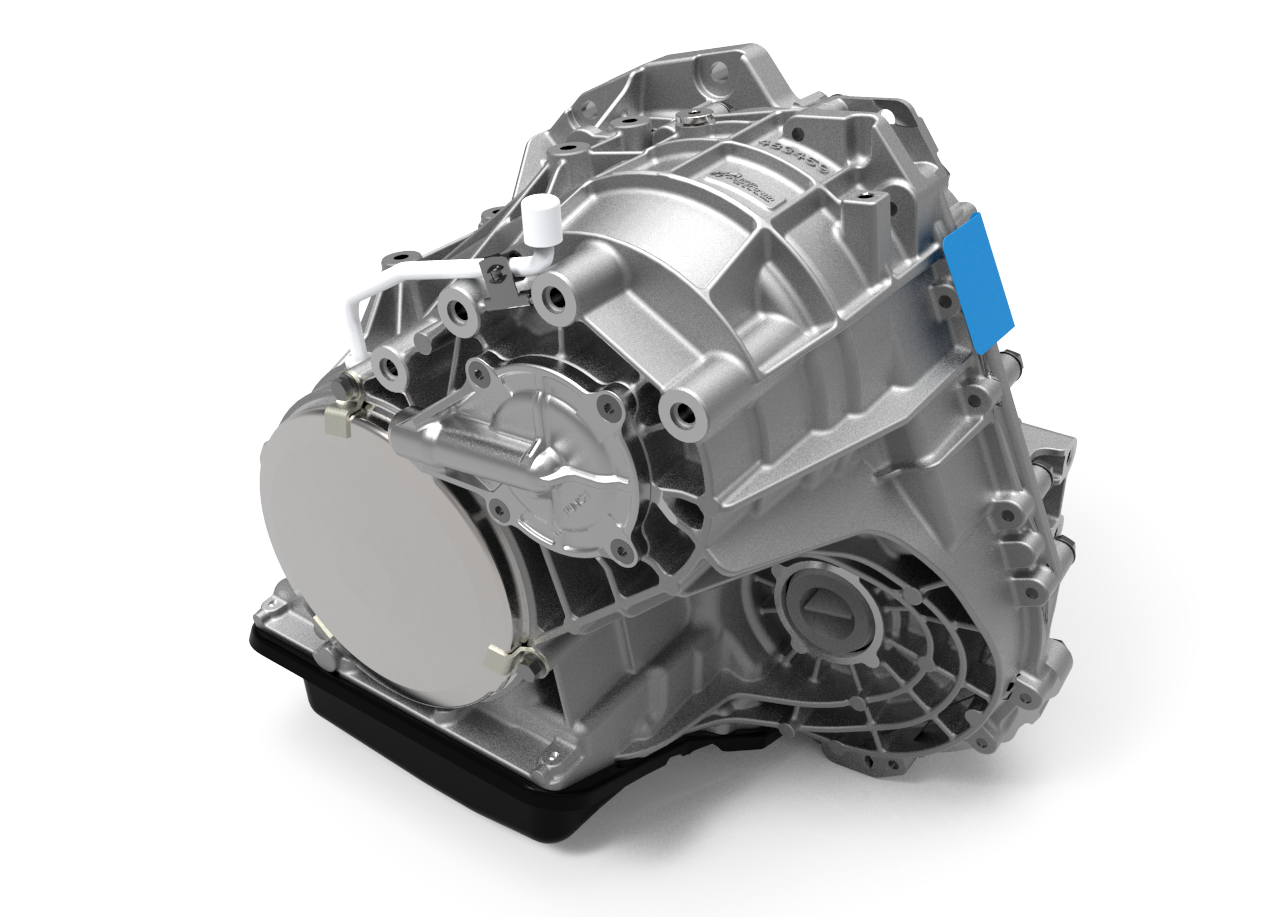

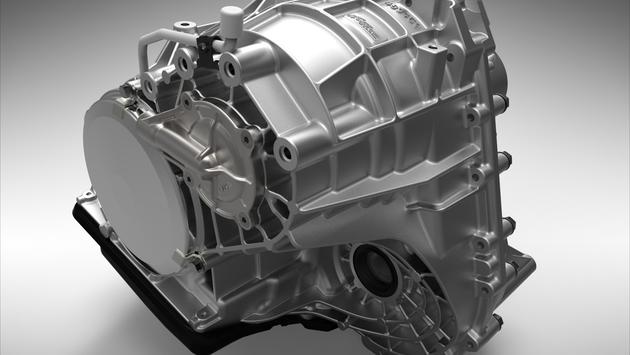

DHT150 Hybrid Transmission

DHT150 has a dual motor P1/P3 architecture and has been designed to operate in combination with sub-2L gasoline engines. Its compact design, with a 342mm axial length, makes it fit even into A class vehicles. Advanced controls and energy management ensure smooth power shifts, high efficiency and up to 35% fuel saving.

Home > Products > Hybrid Drives > DHT150 Hybrid Transmission

Compact design with a 5-axis architecture and fewer shafts, resulting in a smaller transmission. The e-motors with an innovative design using oil cooling rings offer a simple and compact structure.

The low-cost design includes self-developed components such as an inverter, electronic oil pump, and parking mechanism. It uses an electromagnetic clutch that couples power without the need of a complex hydraulic system.

The high-efficiency design includes a full active lubrication system that reduces the amount of lubricating oil needed. The electromagnetic coupling mechanism replaces the wet hydraulic clutch, further improving overall efficiency by 1%.

What makes the DHT150 different:

Compact design

Cost effective

High efficiency

Related news items

10.08.2023-News

Polaris Inc launches the all-new Polaris RANGER XD 1500 with Punch Powertrain CVT for enhanced off-road experience for its patrons

20.02.2023-News

Dongfeng Liuzhou Automobile has presented Punch Powertrain with its “Excellent Supplier Award”

Let us help you define the most suited solution for your application from our wide range of modular and scalable solutions