Testing

Home > Our Story > Our Innovation Leadership & Capabilities > Testing

We aim to integrate as much digital testing as possible to reduce your costs and shorten project timelines

Our key capabilities:

Functionality

- Component test

- Thermal test

- Actuation test

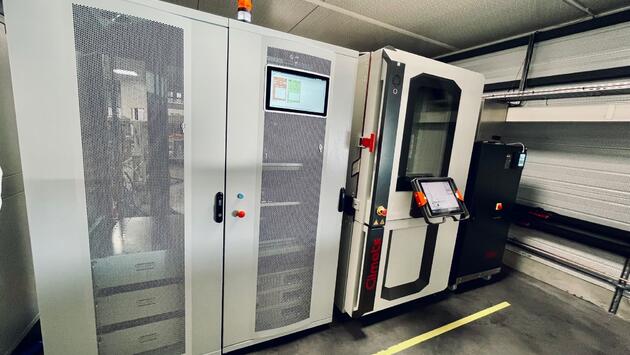

ICE simulation software

- Virtual ICE modeling for e-motor testing

E-motor characterization

- Component verification for speed and torque variations

Component testing

- Hydraulic controls, pumps, valves,…

Durability

- Endurance test

- High cycle fatigue

Thermal cycling

- High and low humidity and temperature tests

Electromagnetic compatibility

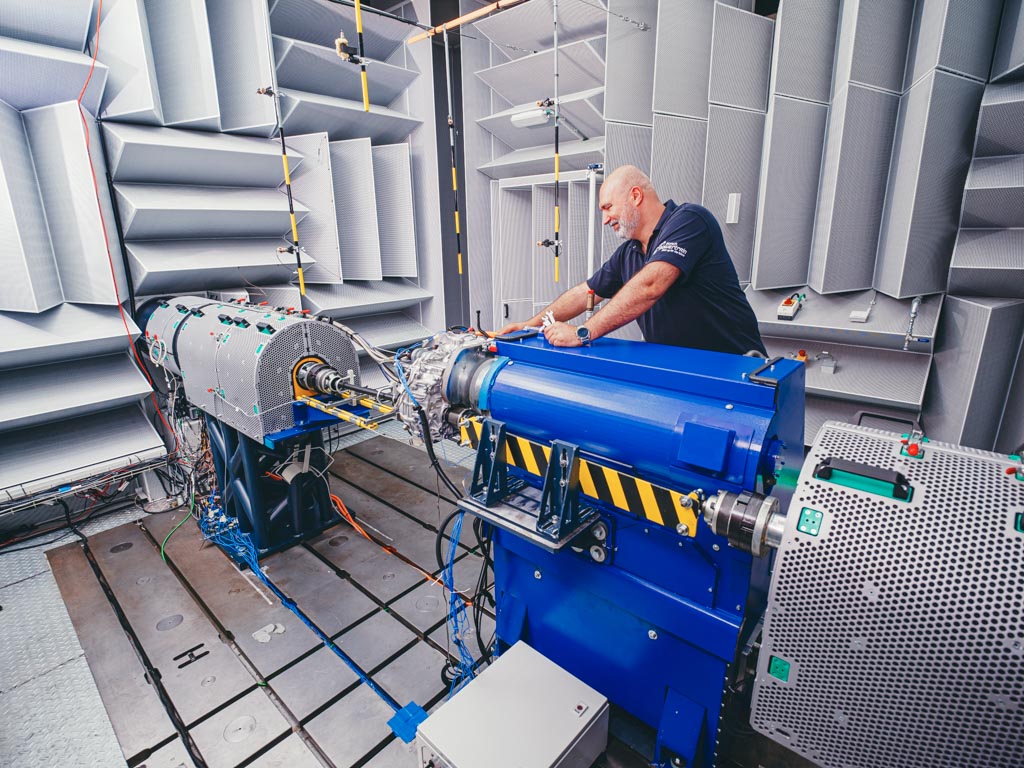

- Overall characterization of electric powertrain on variable conditions

Efficiency

- Worldwide Harmonised Light Vehicles Test Procedure (WLTP)

NVH / Vibration

- Noise and vibration measurements on transmission, car and component level

Calibration

- Advanced calibration of driveability

Beyond state-of-the-art

Punch Powertrain uses a variety of tools and methods to drive solutions to the right direction from the get-go

More efficiency

Our testing skills and capabilities save your time – and money.

Lower environmental impact

Less physical production means less climate impact as a side product

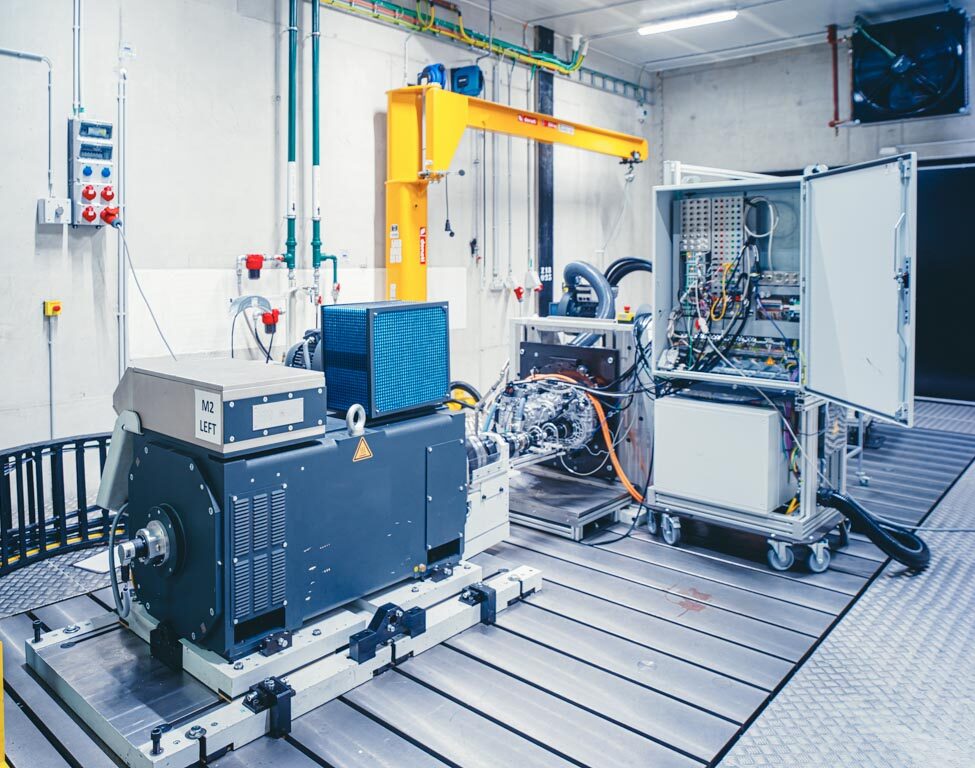

Punch Powertrain developed a highly agile and modular methodology and test set-up to simulate an engine.

The solution comprises a super low-inertia servomotor that is used as input motor to the transmission, a closed-loop controlled with an advanced ICE simulator model.

ICE emulation software enables us to test an engine with high accuracy before physical parts are available. This enables you to reduce the time to market with weeks to months, while at the same time drastically reducing costs and environmental footprint.