- October 30, 2023

The e-DCT transmission was put through its paces during a yearly stringent summer testing. Having spent two weeks in the Spanish heat and steep hills of the Sierra Nevada, the various configurations and applications of the compact e-DCT gearbox accumulated well over 2500 test-kilometers in the severe conditions – unique to Granada. The results were positive, as every thermal validation and altitude compensation test was successful, proving the maturity of the plug-in hybrid (PHEV) e-DCT technology.

The yearly summer tests aim to realistically replicate some of the harshest driving conditions the e-DCT will encounter on the road. The Sierra Nevada, with its constant gradients climbing steeply towards an altitude of 2500m and extreme summer temperatures, frequently exceeding 40°C, enables to test at constant speeds between 50 and 80 kilometers per hour without interruption, at times towing heavy loads, ensuring extensive testing on the clutch.

Testing multitude of scenarios in extreme conditions

With updates being released regularly, these tests are of paramount importance for understanding, analyzing, and improving product features. Rigorous thermal testing is necessary before the final integration into customers’ vehicles to assess drivability at high altitudes, cornering performance, and hill driving in high-temperature conditions. In this testing round, four plug-in hybrids were tested in two different applications. Three of the vehicles were final vehicles from our customer, one was a completely new body and chassis combination.

The results of the efforts are very positive. All thermal validation tests were completed successfully and none of the transmissions reached their limits or showed any grave faults. Additional tests will be carried out in company’s in-house vehicle climate chamber in Belgium.

The results of the efforts are very positive. All thermal validation tests were completed successfully and none of the transmissions reached their limits or showed any grave faults.

Cross functional agile team

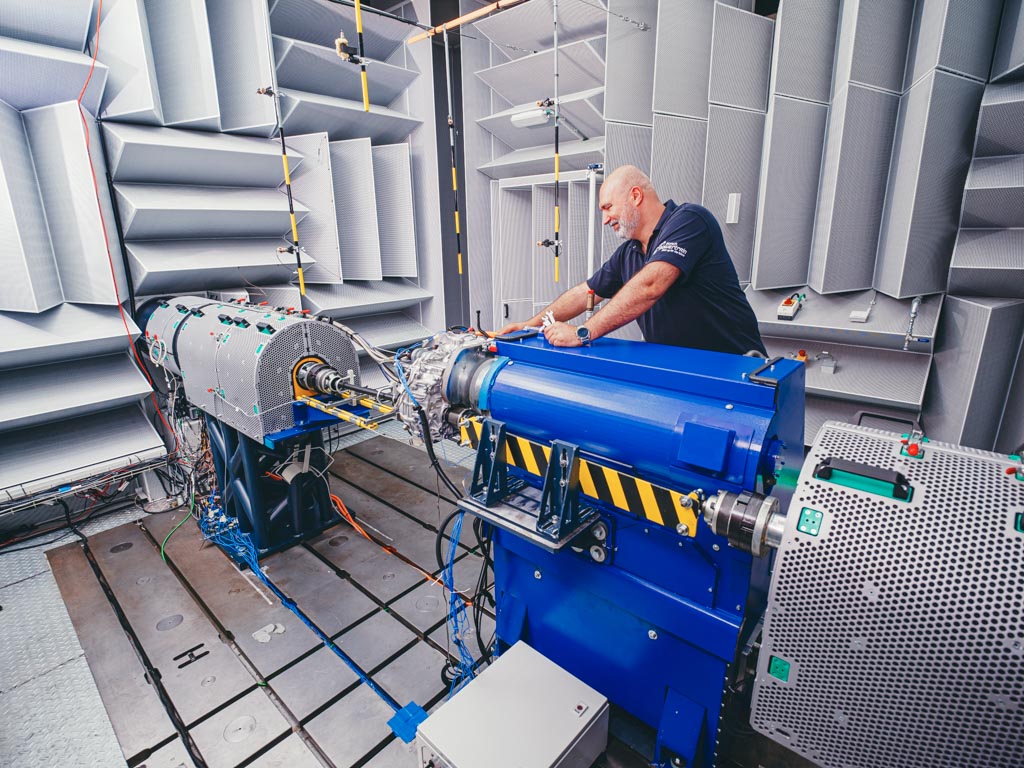

Multiple teams, each with their unique areas of expertise, were involved in preparing for the summer test. The prototype workshop team adjusted the transmissions, incorporating additional sensors, which were subsequently released after testing on the test benches by the testing team. During the summer test, two types of transmissions were fitted in the vehicles: one a standard transmission and the other with additional sensors. Once the transmission was fitted inside the test vehicle, in turn the instrumentation team connected and tested the additional sensors.

The test on location was realized by a cross-functional team of experts: test, controls, software and calibration engineers from our research sites in Sint-Truiden and Eindhoven. This enabled insights into the transmission behavior from various angles, while instantly aligning across disciplines. During the two weeks of testing abroad, the teams were in daily connection with their respective home base, ensuring a fast and lean information transfer.

Winter testing in Finland to follow

More extreme conditions vehicle testing will follow in 2023, with the PHEV e-DCT transmission being built into customer’s vehicles. To assess its performance at extremely low temperatures, an extensive winter test campaign is scheduled to take place in Finland later this year.

Outperforming expectations

Punch Powertrain’s e-DCT comes in a compact, efficient and affordable package. This innovative design approach makes the electric motor an integral part of the highly efficient dual clutch transmission. Easily customized and combined with various forms of hybridization, it swiftly adapts to the market needs, outperforming customer expectations in more ways than one.

Related news items