- February 13, 2024

The annual winter testing proved to be a rigorous trial for Punch Powertrain’s innovative compact e-DCT transmission, subjecting it to the harsh conditions of Finland’s subzero temperatures. Over a span of ten days, the versatile gearbox underwent extensive testing, performing over 70 cold start cycles. The outcome of this testing phase was overwhelmingly positive, affirming the plug-in hybrid’s readiness for mass production.

The yearly winter tests are designed to simulate real-world driving scenarios that push the e-DCT to its limits in cold climates. Snow-covered roads, icy patches, and freezing temperatures provided the perfect backdrop for testing. The significance of these tests cannot be overstated, as they serve as crucial milestones in comprehending, analyzing, and enhancing product functionalities in the most critical situation: cold starting. Stringent cold-weather testing is imperative prior to the mass production and integration of the e-DCT gearbox into customer vehicles. This particular testing round involved four plug-in hybrid vehicles, among which 3 Peugeot 308 mules and a next generation Peugeot 3008.

The importance of oil in cold starting

The focus in cold-weather testing lies in the behavior of the oil in the gearbox. At temperatures of 20 to 30°C below zero, the liquid oil turns into a sticky, almost honey-like substance. This in turn increases friction and resistance between the moving parts. As the oil is used for lubrication, as well as for pressurizing the clutches, the most critical situation is the vehicle start. After sitting in subzero conditions overnight, the thickened consistency makes it hard to pump and reach the necessary zones instantly.

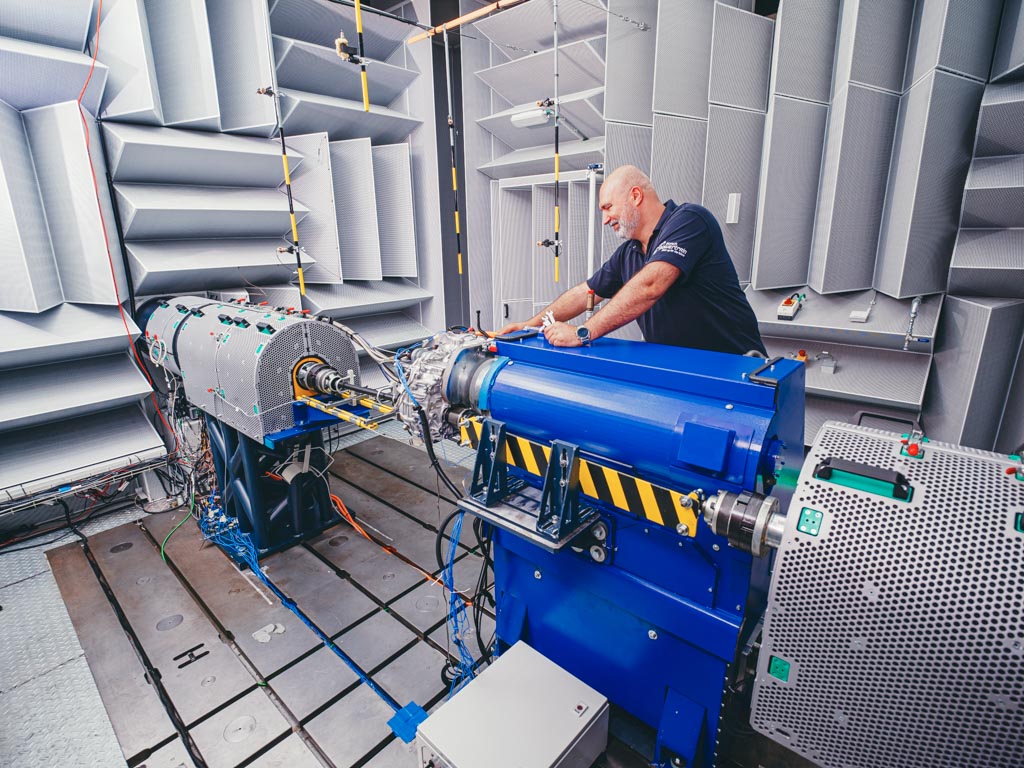

The outcomes of the performed test cycles have proven positive, with all cold-weather validation tests completed successfully without encountering any critical faults or operational limitations in the transmissions. Further assessments will be conducted within the climatic chambers of Punch Powertrain’s facilities, ensuring comprehensive validation of the technology in extreme cold conditions.

Punch Powertrain is delighted to see these positive test results and the introduction of plug-in e-DCT on the roads, as it gears up to become the largest Tier 1 supplier of e-DCTs worldwide by 2025.

Engineering teamwork

The Punch Powertrain team collaborated with the Stellantis and Nidec PSA Emotors engineering teams during the latest phase of winter testing, facilitating the execution of their respective validation plans. The testing took place at Finnish facilities equipped with six climatic chambers, which were efficiently utilized by the three teams involved. The success of the winter testing owes much to the collaborative efforts of multiple teams, each contributing expertise in their respective domains.

A cross-functional team of 8 experts, 1 resident customer test engineer, 2 control engineers and 5 calibration engineers, spearheaded the on-location testing in winter conditions. This interdisciplinary approach provided comprehensive insights into transmission behavior, facilitating seamless alignment across various disciplines.

During the on-site testing, vehicles were equipped with additional sensors to monitor mainly temperature and pressure, overseen by the instrumentation team. While stationed in Finland for the duration of the tests, the teams maintained daily communication with their home bases, ensuring efficient and swift information exchange throughout the testing phase.

This round of testing has confirmed the plug-in hybrid e-DCT transmission is ready for mass production and ready for the roads and . With the mild hybrid transmission variant of e-DCT (MHEV) already on the road, Punch Powertrain is delighted to see these positive test results and the introduction of plug-in e-DCT on the roads, as it gears up to become the largest Tier 1 supplier of e-DCTs worldwide by 2025.

Related news items