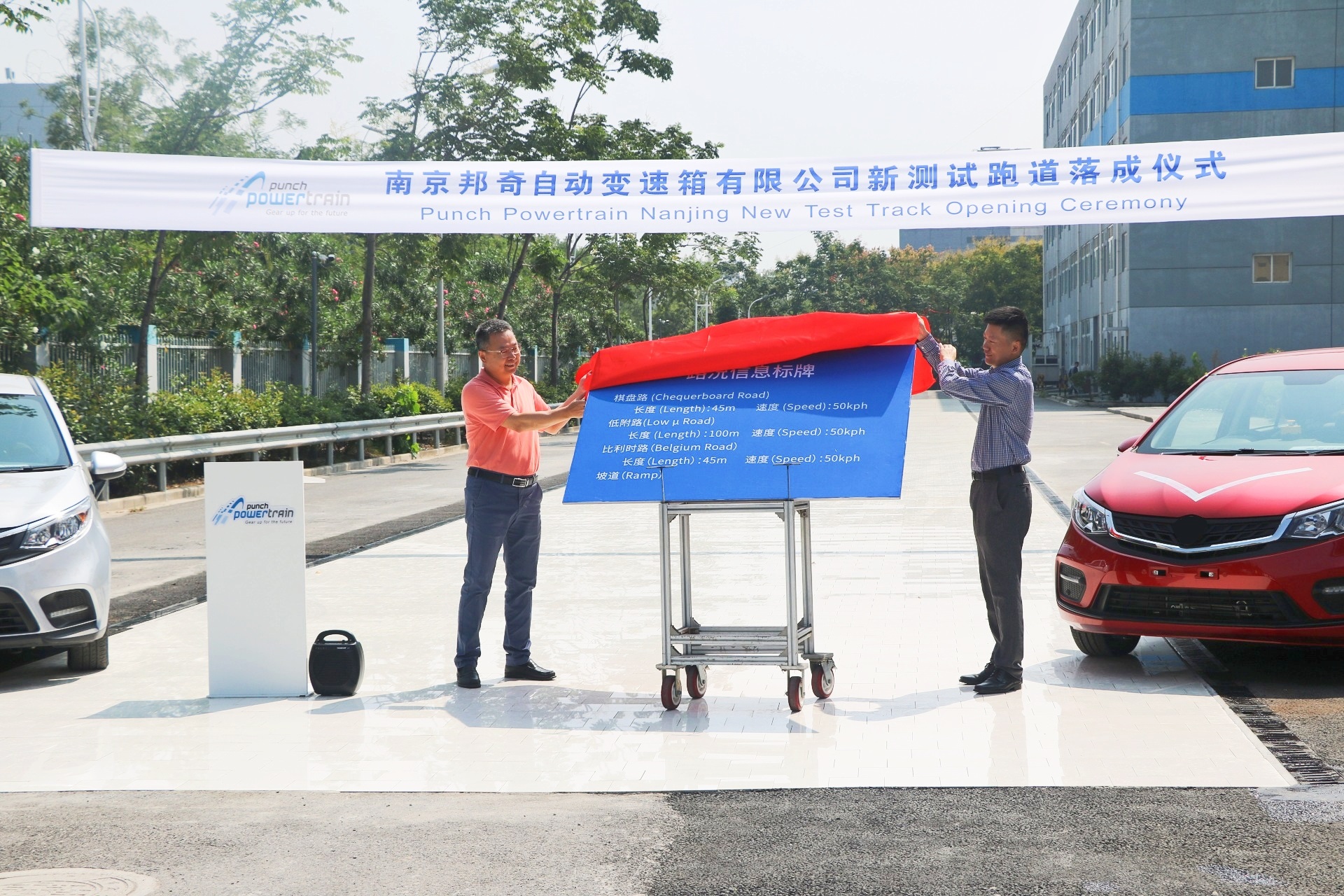

- September 15, 2020

Punch Powertrain Nanjing has successfully inaugurated its fully equipped test track allowing the company to cover the full range of evaluation and validation tests for CVT, DCT and EV products, performed at speeds under 80 km/h. With this milestone, Punch Powertrain becomes the first transmission supplier in China to cover the full testing cycle in-house, offering its customers faster, more efficient and reliable testing. Moreover this marks the full localization of the process and anchoring of expertise in China.

The addition of testing facilities is driven by the clear commitment of the company to its “local for local” strategy, as well as underpins its innovation power. In recent years the company has much expanded its portfolio with additional technologies, such as hybrid and fully electric drive units, as well as dual clutch transmissions, new generation of CVTs and 3in1(Xin1) electric drive systems. The new test track allows the company to fully cover the pre-production testing cycle of these innovations for applications for its Chinese customers in-house, by drawing upon fully localized equipment and expertise.

“We are excited and proud to realize this milestone as part of creating a Competence Center in China!” states Thierry Aubry, President Business Unit CVT/APAC. “This allows us to transfer the know-how to China and broadly expand our local capabilities! This is a critical step in bringing our innovations to the local market and providing customer centric support that is tailored to the local market needs.”

First transmission supplier with fully equipped test track in China

Having this extensive range of testing facilities is not common among Tier 1 manufacturers, nor the OEMs they deliver. With the launch of this test track, adding on to existing facilities, Punch Powertrain becomes the first supplier with a full range in-house test track in China. While the company has already performed its series of CFV and calibration tests for CVT and DCT products, various world class OEMs have expressed interest in making use of the test track in near future.

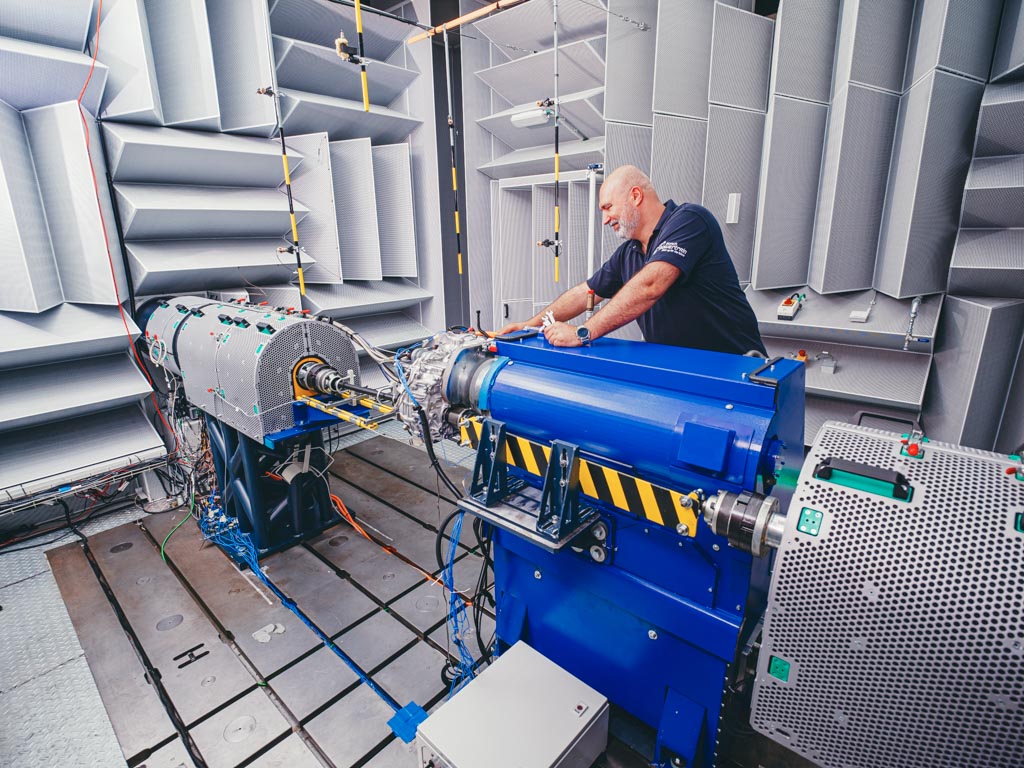

Full range of testing facilities

One of the key merits of new testing infrastructure is the ability to perform the full range of evaluation and validation tests for CVT, DCT and EV products, including the CFV (Clamping Force Validation) test, which is key for transmission and software validation. Existing out of various road surfaces, the test track covers the full variety of the to be validated driving conditions. While this allows Punch Powertrain to offer full in-house expertise to its customers, it also brings a significant efficiency increase in terms of speed and resource allocation.

The overall infrastructure covers following additions:

Straight road consists of a flat rectangular area of 2.800 m² and includes 5 different tracks:

- Asphalt road – representing rough surfaces.

- Low μ road – low friction road, simulating driving conditions in snow, water or ice, needed for ABS, TCS and ESP testing.

- Chequerboard road – performing a similar function as low μ road, encompassing surface changes between tiles and concrete.

- Belgian road – also known as ‘setts’, simulating bumpy conditions of cobblestone roads.

- High curb road – simulating driving off a high curb.

Gravel road consists of a flat rectangular area of 600 m², combining gravel and concrete surfaces to simulate various off-road situations.

Related news items