- April 20, 2022

Home > News > Development > Expert customization for test benches – from race track to road

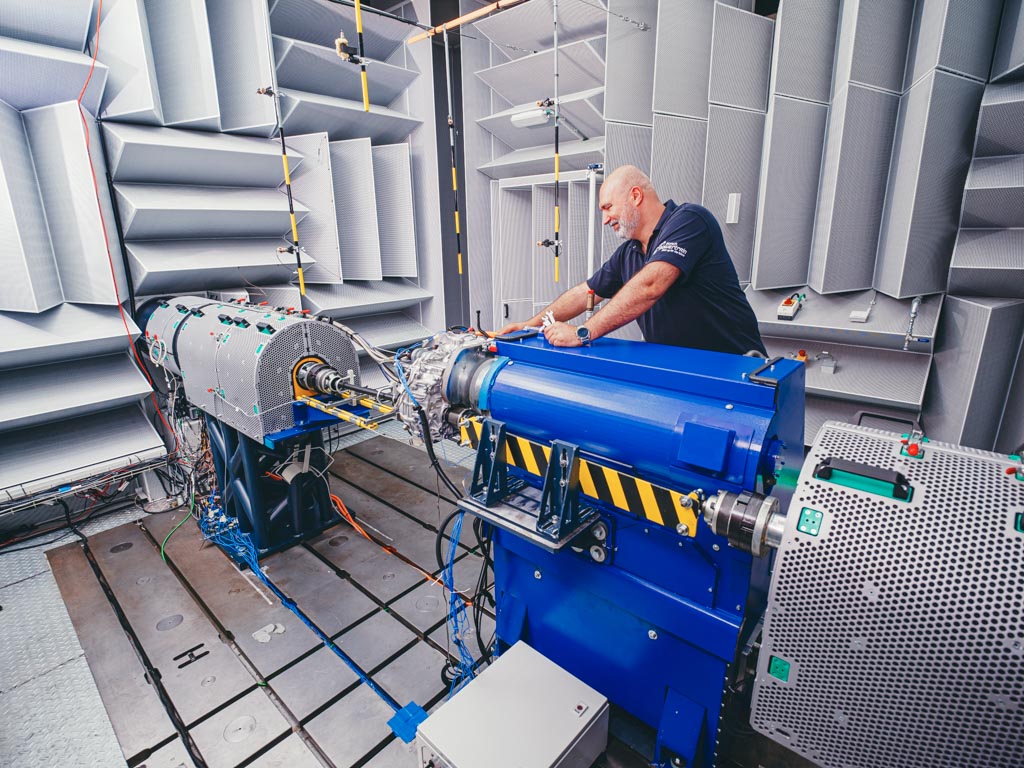

At Punch Powertrain, building test benches rests on a foundation of product expertise. These high-end benches, used in Formula 1 and E, are made to best fit the needs of transmission manufacturers, and can even be designed specifically for individual clients. Benoit Briane, R&D Leader Inverter and Rama Mboungou, Power Electronics Test Leader at Punch Powertrain explain what’s different in the way Punch Powertrain approaches test benches.

At first glance it might sound strange that a powertrain expert such as Punch Powertrain also builds test benches. Yet it turns out their deep product expertise allows them to outclass more generic test bench suppliers. “Our focus is not on the bench, but on the product that goes on the bench”, says Briane. “That makes a huge difference. A company can of course use a generic test bench, but it will limit what you can do, because every OEM has their own specificity. We understand the product on the bench, which means we can make a bench specific for a type of validation or product. Our test rigs fully answer the requirements of the partner. An inverter test bench for example needs certain, very specific, characteristics, such as max performance validation, efficiency measurements and safety features like overcurrent or loss of ground, that you might not find in generic test benches.”

Technical End of line testing

One example of where this makes a difference is on end of line test benches. These are challenging to make and validate. They need to function under adverse conditions in a manufacturing environment, and simulate all the relevant conditions to validate the reliability of the assembly process. They also need to do performance checks on key parameters and functions, while at the same time measuring the responses of the equipment that is being tested. “To do this, you not only need to know how to make a test bench, but also what is expected of the product”, says Briane. “By understanding both the product and the testing we can deliver something that is efficient, fits the needs of the client and can be adapted.”

Beyond end of line testing, Punch Powertrain also offers a wide variety of test benches. These include functional and reliability tests, but also environmental and emissions checks. The Punch Powertrain team takes a holistic view on test benches and works together with the customer to develop a product tailored for their needs.

Formula 1 and E

Punch Powertrain’s expertise in test benches is also proven in racing. The company is involved in both Formula 1 and Formula E, where they supply products, and the state-of-the-art test benches to validate them. For a major German car manufacturer, Punch Powertrain developed an inverter that could handle up to 250 kW, which in turn required a separate project for a test bench. “Our people were on the one hand designing the inverter, but also the test bench to validate it”, says Mboungou. “Both teams were working together, which allowed us to reach 250 kW. This in turn gave us a great amount of experience that we will be able to use in other projects.”

Development of electric vehicles requires comprehensive tests of each component, such as HV battery emulation, e-motor emulation and testing the traction-inverter. By pushing up to 250 kW the Punch Powertrain team gained experience in combining these tests with high power levels, pushing the envelope on electrical testing of power inverters.

High-end racing projects in this way create strong synergies where technology developed for the race track can find its way down into road cars. It also taught the Punch Powertrain team to work in new ways, capitalising on their agility and innovation drive. “The timeline for Formula 1 or E is totally different compared to a classic car project”, says Briane. “You need to be much more agile. It also requires a lot of reliability. It gave us insights in how to develop in fast and reliable ways, which we can today apply to our more classic test benches for road cars.”

Test benches as-a-service

The bigger goal for the team is always to best serve the client. “We design test benches for our partners that fit their applications”, concludes Briane. “But we can also offer our expertise. If a partner wants to design a test bench themselves, then we can support them just as well. We understand both sides of the coin.”

Related news items