- January 28, 2025

The automotive industry is rapidly transitioning towards 800V architectures in electric vehicle (EV) batteries and systems, establishing 800V as the dominant market category for mid-to-high-power systems over the next decade. Recognizing this trend, Punch Powertrain has developed the IV5—a cutting-edge 800V high-power inverter. This product leverages the company’s extensive expertise in electric and conventional motorsport, SiC technologies, and advanced high-power architectures.

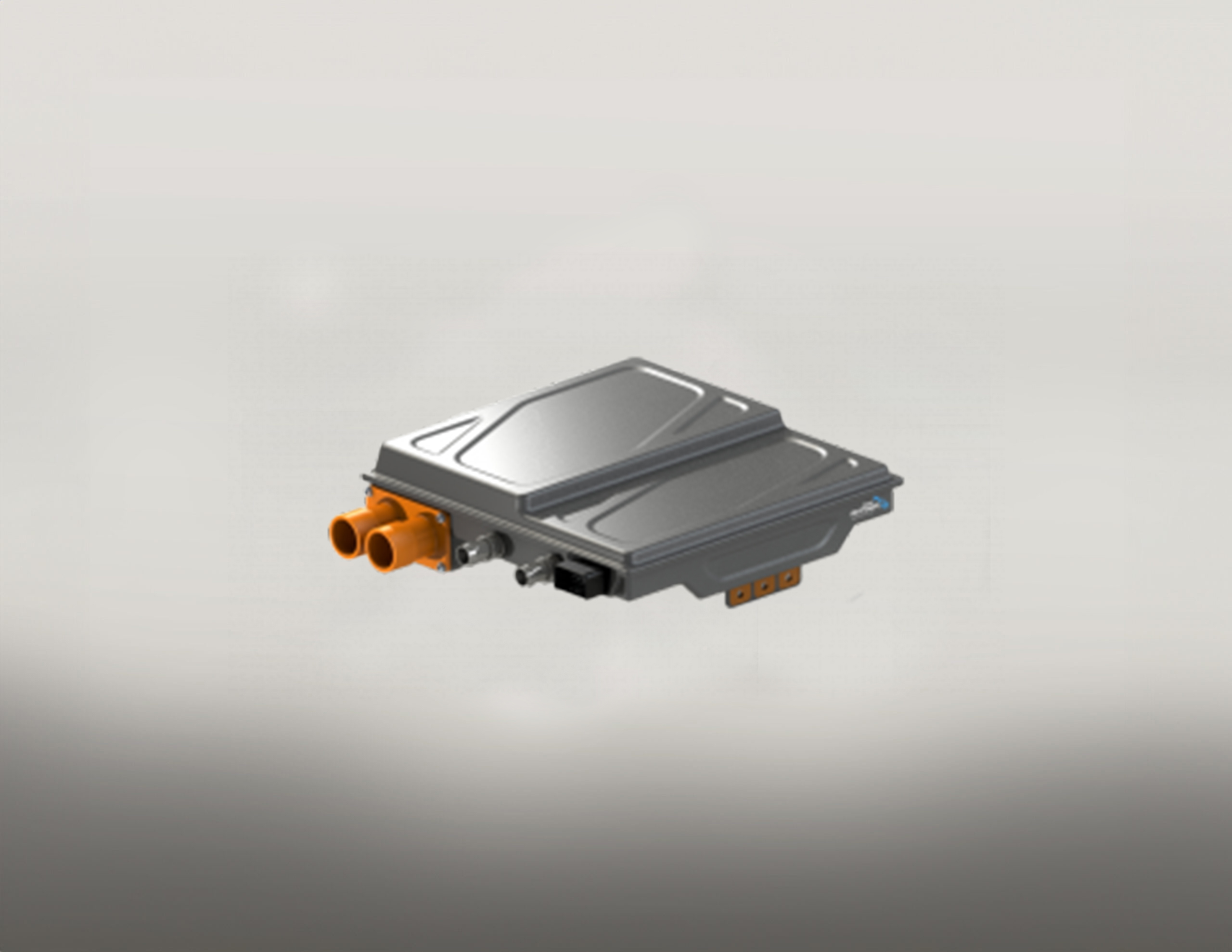

Overview of the IV5 Series

The IV5 Series encompasses a range of compact, durable, and high-performance inverters designed with adaptive technology, making them ideal for integration into various demanding environments. The series features a highly flexible and scalable design, enabling the product shape and volume to be optimized for specific applications. Furthermore, the IV5 is compatible with integration into any X-in-1 electric drive unit (EDU) configurations, providing unmatched versatility for diverse automotive applications.

-

Key Features of the IV5 Inverter:

- State-of-the-Art 800V Inverter Family: Scalable from 200 kW to over 400 kW for mass production.

- Compact Design: Up to 10% more compact than competing solutions.

- Recyclability: Developed in collaboration with MTB, a leading recycling partner, to enhance end-of-life recyclability.

- Integrated TCU Functionality: Optional integration of transmission control unit functionalities.

- High Power Density: Optimized for maximum performance in a compact form factor.

- High efficiency: Up to 99.6% efficiency using the most of SiC technology. Product design also performs very efficiently in lower power region by HW and SW unique strategies.

- Weight Optimization: Significant weight reduction compared to competing products.

- EMC Compliance: Fully compliant with CISPR 25 Level 3 standard.

- Technology Bricks: Built upon internally developed and validated modular technology platforms to minimize development time and increase robustness.

- Advanced Software: Utilizes AutoSAR 4.2.2 software, using common Punch Powertrain platform as IV1 and IV3 products.

- Safety and Connectivity: Designed to meet Cybersecurity (CySe), Firmware Over-the-Air (FOTA), and ASIL D requirements.

Punch Powertrain’s IV5 inverter represents a significant step forward in EV propulsion, combining cutting-edge technology with sustainable practices to meet the evolving demands of the automotive market.

Applying advanced EMC testing methods

Punch Powertrain’s R&D team has cultivated a high level of expertise in electromagnetic compatibility (EMC) testing, particularly for inverters. This expertise enables early-stage pre-validation of designs using virtual samples, significantly reducing upfront costs. By identifying and resolving potential design challenges early, this approach enhances product robustness, shortens physical validation timelines, minimizes development delays, and reduces costs—ultimately ensuring customer satisfaction and maintaining trust.

Collaboration and Future Integration

Together with partners and prospect customers, we’re currently researching the integration of IV5 with high performance emachines including axial flux. We experience demand for disruptive ultra-compact eDrives for performance EVs, Hybrid SUVs & light trucks as well as heavy commercial e-vehicles and target for a leader position in these segments.