Home > News > Innovation > Powering Innovation — Joint High-Performance Axial Flux eDrive Testing by Punch Powertrain and Traxial

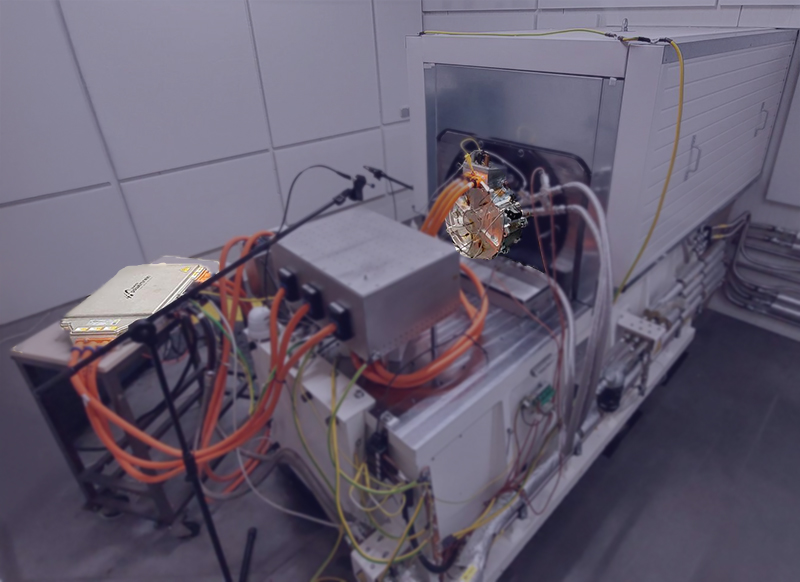

Punch Powertrain, a global provider of innovative propulsion solutions, and Traxial, a technology leader in high–performance yokeless axial flux electric motor technology, successfully completed a joint high-performance test campaign in May 2025. The goal was to validate the technical compatibility and performance of their latest cutting-edge propulsion technology under high-demand operating conditions.

This collaboration between two Belgian technology leaders highlights the strength of local innovation driving global electrification developments.

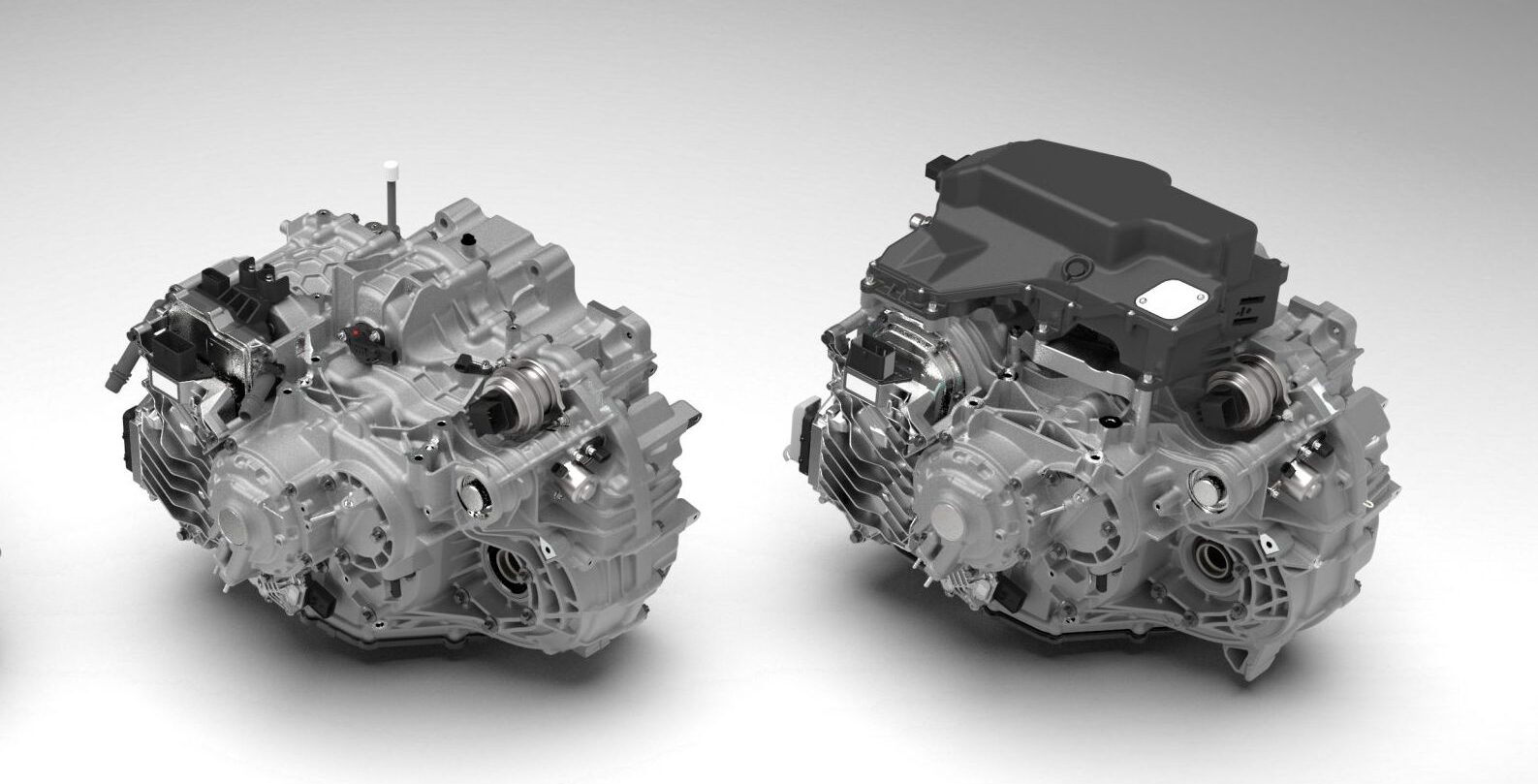

This collaboration paired:

Punch Powertrain’s IV5 800V Silicon Carbide (SiC) inverter : a compact, high-frequency, high-power inverter scalable up to 400 kW.

Traxial’s next-generation axial flux electric motor : a compact, high torque and power dense electric motor, that delivers 300kW peak and 270kW continuous at maximum speed.

Maximum Power (kW) : 310 kW

Maximum Torque (Nm.): 730 Nm (700 Arms) or 600 Nm (500 Arms)

Joint Milestone Achieved — Tests Completed Ahead of Schedule

All planned testing activities were successfully completed one week earlier than scheduled, with zero faults or system limitations. This reflects:

- The excellent preparation and close collaboration across system, Power Electronics, validation and software teams from both companies.

- The maturity of the products to ensure a smooth integration and fulfilling performance expectations.

The excellence in operation with the right competencies at the right place to overcome this integration challenge.

Key Test Results

|

Test Parameter |

Result |

|

Phase current (IV5) |

✅400 Arms |

|

Continuous power (IV5) |

✅ 270 kW (target achieved) |

|

Peak power (IV5) |

✅ 300 kW (limited by test bench) |

|

Switching frequency (IV5) |

✅ Up to 18 kHz at full power |

|

Control strategy (IV5) |

✅ SVPWM with harmonic injection implemented |

|

Thermal behaviour (IV5) |

✅ Stable and within expectations across multiple scenarios |

|

Phase current (AXF300) |

✅400 Arms, sustainable with normal cooling up to 8000rpm, possible with optimised cooling up to 10000rpm. |

|

Continuous power (AXF300) |

✅ 270 kW (target achieved) |

|

Control strategy (AXF300) |

✅ SVPWM with harmonic injection implemented, showcasing improvements in critical NVH regions. |

|

Thermal behaviour (AXF300) |

✅ Stable and displaying outstanding cooling capabilities above simulated rated currents. |

These results confirm the high level of maturity and real-world readiness of both systems under rigorous electrical and thermal operating conditions.

System Synergy and Integration Benefits

The pairing of Punch Powertrain’s IV5 inverter and Traxial’s axial flux motor offers:

- Extremely short build lengths , enabling compact co-axial drivetrains.

- High power density , with potential to reach ~6 kW/kg in twin-motor torque vectoring configurations.

- Robust thermal management , with no derating across full performance range.

- Excellent NVH behavior, by digitally controlled harmonic injection.

These results mark a solid step forward in building compact and powerful systems that support the shift to cleaner mobility. Punch Powertrain and Traxial continue to promote their technologies as components, subsystems, or complete propulsion solutions for OEMs worldwide.

Application Fit

This compact and high-performance system is ideal for:

- Plug-in hybrid, Dedicated Hybrid and Range Extender Vehicles at both 400V and 800V levels.

- Twin-motor electric drive units (EDUs) for high performance BEVs.

- Electric commercial vehicles (eCVs).

- Non-automotive mobile applications in off-highway/construction, marine, aviation, and energy sectors.

Validation of Engineering Readiness

Following a successful stand-alone inverter testing campaign covering functionality, EMC, and reliability, the complete system was operated at full power using an internally developed silicon carbide inverter.

The AXF300-85s motor is the latest product launch by Traxial, designed for single and multi-motor architectures. After completing the A-Sample validation and reaching the 300,000km durability milestone with an internally developed silicon carbide inverter.

These results mark a solid step forward in building compact and powerful systems that support the shift to cleaner mobility. Punch Powertrain and Traxial continue to promote their technologies as components, subsystems, or complete propulsion solutions for OEMs worldwide.

The IV5 inverter is subsidized by Bpifrance under the France 2030 plan, highlighting its role in advancing next-generation electric propulsion systems.

Related news items