- December 14, 2018

Home > News > Development > Punch Powertrain opens ‘The Learning Factory’ in Sint-Truiden

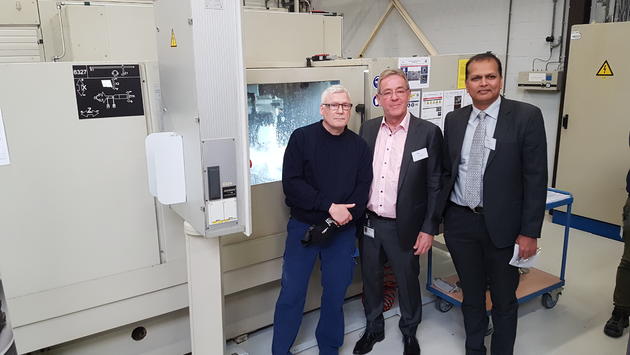

Punch Powertrain focuses strongly on innovation and the people that actuate this innovation. To guarantee continued development, Punch Powertrain invests in ‘The Learning Factory’ that was officially inaugurated on December 13th, by CEO Cor van Otterloo. Besides training rooms, this training centre is also equipped with more than 400m² of simulated production environment, that allows for a wide array of industry-specific techniques to be taught and trained.

Continued training

Our rapidly growing organisation requires continued training of employees for specific roles and functions. We have known a strong growth spurt over the past few years, while even at a normal progress a considerable number of new employees need to be trained and the current employees need to be trained for new technologies.

Up to now, the specific training sessions were limited to largely training-on-the-job, coached by experienced co-workers. The Learning Factory allows us to instruct new people in these technologies without any production pressure.

Industry-specific techniques

The scarcity in the labour market for technically-skilled profiles forces us as a company to provide in more basic training. We have a number of strong partners to support us, such as VDAB and Limtec. However, specific techniques that are unique and only for our company, such as grinding techniques and certain measuring techniques, cannot be taught by an outside company.

Cooperation with educational institutions

We will also allow for schools and educational institutions to use our Learning Factory. This way, students will have the opportunity to apply their theoretical knowledge on machines and measuring devices in practice; something that more often than not was impossible due to the high investments that were needed for the training materials. Right now, 4 secondary schools nearby are working out a programme for their senior students in Mechanical Design Techniques. There are also some exploratory talks ongoing with UCLL, PXL and UHasselt.

A few examples of the training programme:

- CNC training: For this training, an actual CNC machine is brought out of production to instruct maintenance engineers and CNC operators in a real-life setting, without the usual production pressure, often pushing the training process to the background. This training includes basic and CNC-grinding techniques, such as: machine set-up, grindstone dressing, grindstone replacement, first-line maintenance, MSA visual inspection, etc.

- Grinding techniques: to train the ‘feel of the micrometre’, we purchased a conventional (non-digital) grinding machine. Manually setting up the machine to a thousandth of a millimetre gives a much better feeling of the product rather than just simply entering some digits on a keyboard. Process operators can also practice their calibration skills on this machine: measuring and building tools, registering recordings, etc.

- Measuring techniques: this training allows for measuring engineers and operators to become skilled in every possible measuring technique and Statistic Process Control (SPC).

We supply the most advanced measuring devices, such as: passameter, intramess, roughness coefficient meter and a 3D measuring device. - Maintenance: to train maintenance engineers in practice on the basic principles within the Total Productive Maintenance (TPM), we acquired 9 learning booths. These include: electronics, hydraulics, pneumatics, lubricating, drive system techniques, 5S, safety, diagnostics and machine knowledge.

- Safety: we attach a great deal of importance to safety, which is why we supplied a dedicated learning booth where the use of personal protective equipment can be practised.

- Transport: There are several certificates for a variety of transportation tools, such as the stacker, reach truck, forklift or travelling crane. As important is the space that has been specifically dedicated to this training; by moving the learning environment from the production floor to a dedicated learning centre, the stress and risk of accidents are decreased significantly.