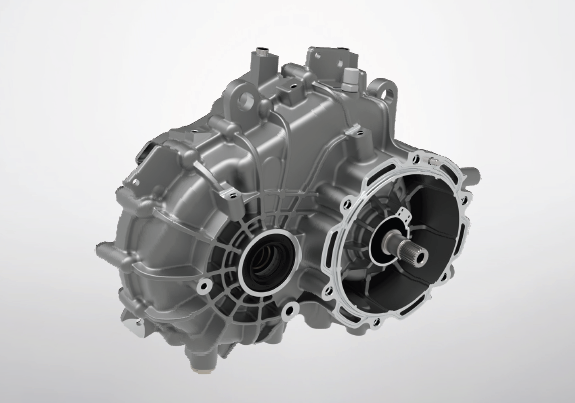

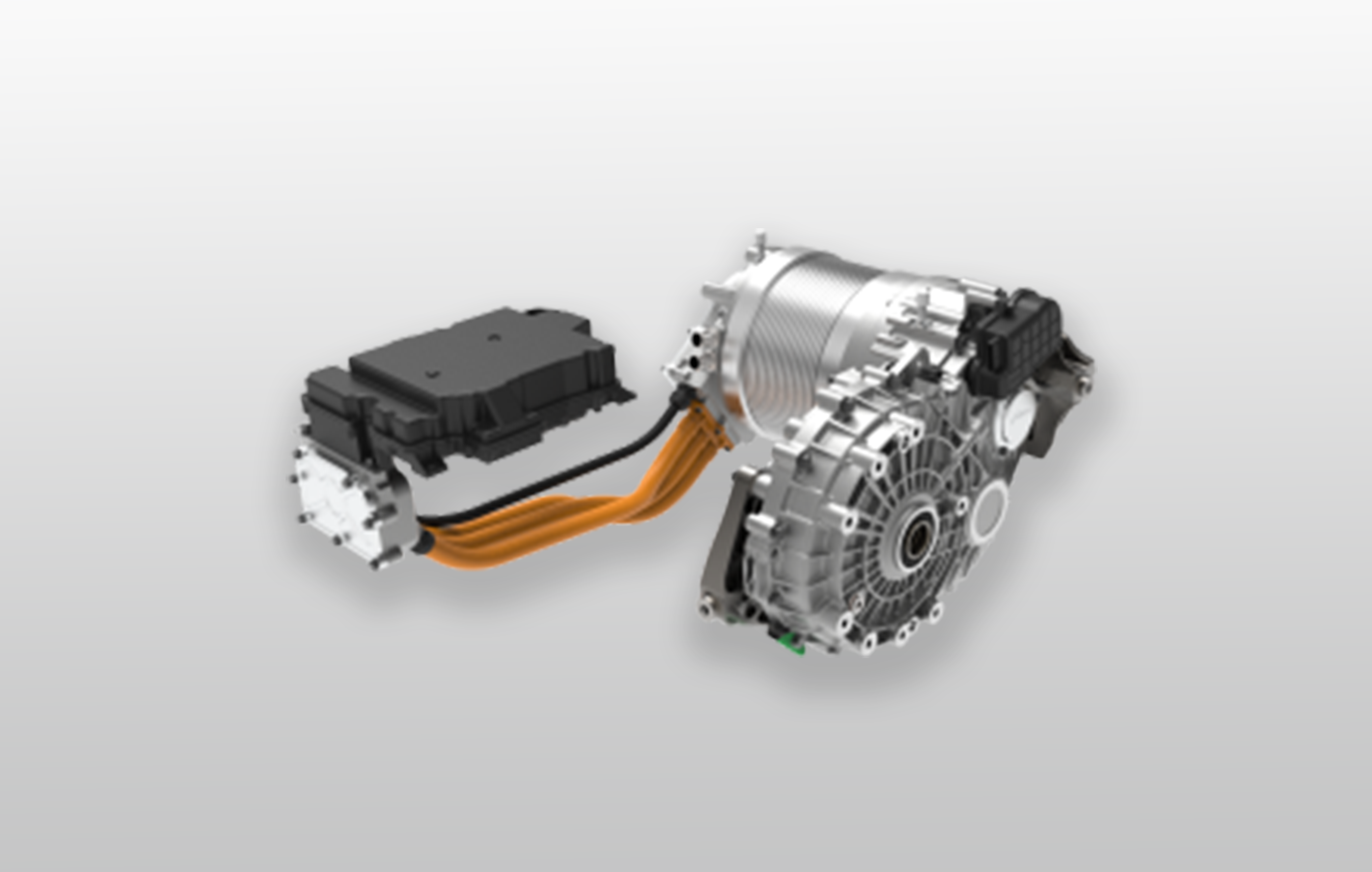

In the rapidly evolving landscape of electric vehicles (EVs), every component and sub-system plays a crucial role in optimizing performance, efficiency, and overall driving experience. Among these sub-systems, the EV reducer stands out as a key element in translating the power from the electric motor to the wheels with precision and efficiency. As we delve into the intricacies of Punch Powertrain’s EV transmissions, Joris Bronckaers, Engineering Leader EV, sheds light on what makes Punch Powertrain’s reducer excel in the industry.

The fundamentals of an EV reducer

The question arises: why is a reducer necessary in an EV drive unit? And why isn’t it sufficient to directly bolt the electric motor to the wheels? Bronckaers explains this by highlighting the torque needed to get a 2-tonne vehicle moving from a complete standstill. The size of the e-motor capable of such figures would surpass the practical, as well as the reasonable, in terms of size and weight. A reducer uses a gearing system allowing for a relatively small motor to develop high wheel torque in low speed range and also be able to fulfill the basic criteria of driving comfort and achieve proper mileage.

No secret, just experience and effort

With over five decades of experience in transmission systems, Bronckaers emphasizes the importance of leveraging Punch Powertrain’s expertise to elevate their design of EV reducers. Although the concept of a reducer is pretty straightforward, making it into a modular design requires meticulous attention. Factors such as noise, vibration and harshness are critical aspects for enhanced customer driving experience, which become ever more important when no combustion engine is present to mask the transmission noise and vibrations.

Efficiency remains the most relevant factor. With a reducer accounting for about one third of the losses in a next-gen electric drivetrain, a poorly designed reducer can drastically bring down autonomy levels. As each reducer undergoes cooling and lubrication, Computational Fluid Dynamics (CFD) is used to make incremental improvements at the gear, bearing, or oil seal levels. These enhancements collectively result in significant reductions in losses, thereby improving the efficiency of an EV reducer.

Punch Powertrain is at the forefront of delivering superior solutions to meet the evolving demands of the electric vehicle industry. As EV technology continues to advance, the role of sub-systems, like the EV reducer, will remain pivotal in shaping the future of sustainable mobility.

“What makes the difference between a good reducer and an exceptional one is the effort you put in it” says Bronckaers. At Punch Powertrain, the 20/80 rule is a well-known concept. It states that if you put in 20% of the know-how, you get a half-decent reducer that performs at 80%. In a bid to squeeze out that extra 20% quality, the engineers at Punch Powertrain rely on decades of accumulated experience that brings the 100% knowledge to the table. What comes out is a reducer that fully meets the needs of the customer.

A modular approach to reduce cost and development time

All these years of accumulated know-how have made it so that Punch Powertrain has the technical capability to deliver a tailored reducer in under a year. By using “tech bricks” in its E-Propulsion Technology Kit, Punch Powertrain has the ability to quickly add functions that suit the customer’s demands. These range from a locking function that acts as a park brake, engaging an axle to switch from two-wheel drive to four-wheel drive when needed, or a multi-speed function. The use of these tech bricks not only streamlines development processes but also enhances cost-effectiveness, eliminating the need to start from scratch in every new project.

Another added benefit of being an industry leader for over 50 years means Punch Powertrain has the ability to count on its own trusted supply chain. By collaborating with innovative suppliers and leveraging the latest technology, they ensure that every component meets the highest standards of quality and performance. While affordability is a priority, the emphasis remains on delivering value through cutting-edge solutions and reliable timelines. Punch Powertrain is in itself an important part of the EV industry supply chain. Not only does it furnish car manufacturers directly, but acts as a key supplier for major Tier 1s too.

The evolution of EV power transmission relies on advancements in sub-systems, such as the EV reducer. Through a combination of expertise, innovation, and collaboration, Punch Powertrain is at the forefront of delivering superior solutions to meet the evolving demands of the electric vehicle industry. As EV technology continues to advance, the role of sub-systems, like the EV reducer, will remain pivotal in shaping the future of sustainable mobility.